TUM’s course review: Six Sigma – Define and Measure

Learn how to collect accurate data with useful tools and techniques for process improvement, with many examples.

The Six Sigma: Define and Measure course is provided by the Technical University of Munich (German: Technische Universität München) which is a public research university in Munich, with additional campuses in Garching, Freising, Heilbronn, Straubing, and Singapore.

A University of Excellence under the German Universities Excellence Initiative, TUM is consistently ranked among the leading universities in the European Union. It proposes 14 courses on EDX and 2 programs.

Why I took the course

Introduced by American engineer Bill Smith in 1986, Six Sigma (6σ) is a combination of tools and techniques for process improvement. When a process has an implementation of six sigma, it will produce 99.99966% free of defects for a given feature. This can be achieved by removing the causes of defects and minimizing variability, using empirical and statistical methods.

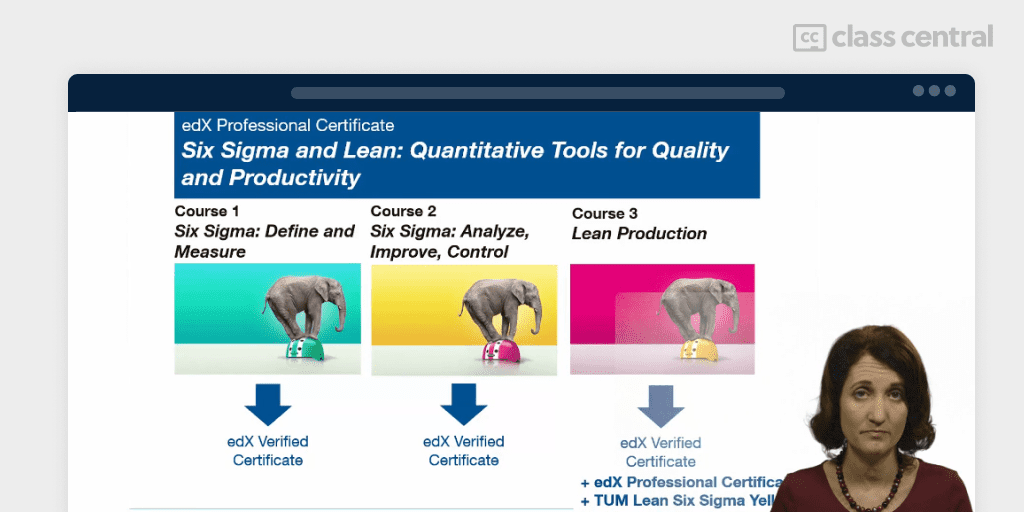

While my studies were in physics, I am nowadays leading the production department of my company and wanted to get a better knowledge of the field. That is why I started the course, to be followed by the recommended courses of Six Sigma: Analyze, Improve, Control and Lean Production.

The Course

The course starts introducing notions in the chapter and then clarifies them through more and more complex examples. The practice exams give you a very good indication of your grasp of the course.

The course chapters are the following:

- Introduction to Six Sigma: The impact of defects and how to measure them

- Understanding Customer Expectations: How to define what matters in your product and what to focus on first

- Statistics Review: Statistic tools and understanding them

- The Normal Distribution: A fundamental mathematical tool to calculate the key parameters of production processes

- Process Mapping: Detecting the process that need improvements first

- Measurement System Analysis: The description of measurement analysis, making the difference between precision & accuracy

- Process Capability: Gives tools on evaluating the ability if a process to produce with satisfying quality

- Quality Topics and Course Summary: Failure mode and effect analysis

Each chapter is concluded by a graded homework. The recommended five hours a week is a reasonable time to invest to be able to pass the homework successfully. Chapter 2 & 3 have additional homework where you are evaluated by other students and have to evaluate them. The idea is nice, but the execution success depends on each student’s participation.

How to succeed

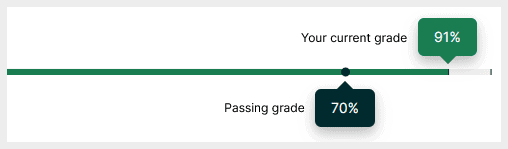

My final grade is 91%, for a passing grade at 70%. Except for two exams where I made one mistake, all the others were fulfilled perfectly, except for the first peer-graded exam where I had a low score. Thankfully, deadlines can be postponed, which is very convenient when you are working. For the exams, I wrote some Python scripts to quickly do the calculations. A good grasp of statistics is definitely useful to succeed.

After this course I’ve started the following one, which is Six Sigma: Analyze, Improve, Control.

Key Takeaways

- The course is well taught.

- It provides many examples which help you get a good understanding

- The usefulness for work is quickly visible

- The required time investment is compatible with your work activities