TUM’s course review: Lean Production

Learn how to apply key elements of Lean Production, from minimizing inventory and reducing setup times, to using 5S and Kaizen

Hello my name is Argus Agisilaou. I live in Melbourne, Australia, and work in Operational Excellence at NAB, one of Australia’s four largest financial institutions in terms of market capitalization, earnings and customers.

I have really enjoyed and found the Lean Production course by the Technical University of Munich extremely useful! The theory and explanations are followed by real life examples and case studies which ties everything together, and helps everything make sense i.e., what to use, when and how.

The Lean tools have been very helpful, as well as the advantages and disadvantages of Lean and Six Sigma, and how the two methodologies tie together has been invaluable.

Why I took this course?

“Learn how to apply key elements of Lean Production, from minimizing inventory and reducing setup times, to using 5S and Kaizen, in order to improve quality and productivity in your workplace”

I loved the idea of improving my knowledge and learning new skills utilizing all the advantages of an online learning platform. Having the ability to access course content at any time or location, as many times as I want, was very convenient. Being a student of a university located in Munich while living on the other side of the world was kind of fun, even more so during these times of restricted travel!

The course is also extremely affordable; the cost is very reasonable especially when you consider the quality of teaching and content provided. The way the course is structured and taught effectively transfers the knowledge and concepts to the students. What is Lean Production about? It examines how the principles of Lean production improve quality and productivity and enable organizational transformation. You also learn about Lean Management, a customer-centric methodology that improves processes by eliminating waste and focusing on value-added tasks. All things that really matter!

The instructors and exchanges

The lecturer for most of the recorded lectures is Professor Holly Ott. She is a professor of Production Management and IT Systems at the University of Rosenheim Applied Sciences and Management, a senior lecturer at the Technical University of Munich and an adjunct professor at Singapore Management University (Singapore), IE Business School (Madrid) and Syracuse University (New York). She holds a Ph.D. in electrical engineering from the University of Virginia and has worked for twelve years in quality and supply chain management in the USA, Europe and Asia for Siemens, Motorola, IBM and Infineon.

There’s much, much more including holding an International Association for Six Sigma Certification (IASSC) Certified Lean Six Sigma Green Belt (ICGB) and being a member of the American Society for Quality (asq.org).

It is safe to say that Dr Ott really knows her stuff, is passionate about it, and just as importantly, translates it into her lectures. She’s very approachable, quickly responding to emails and queries on the subject discussion forum. In addition, there are guest lecturers who are experts in their field.

What does the course cover?

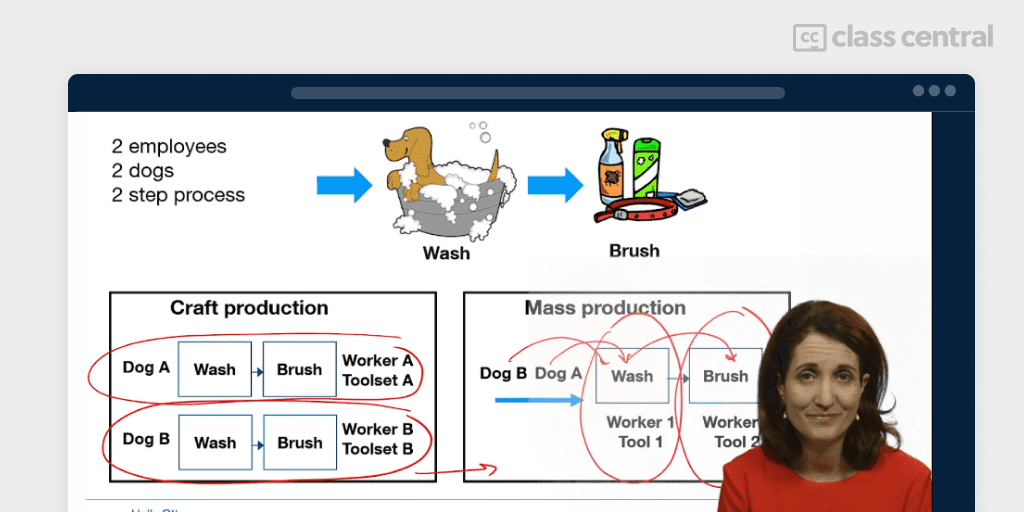

The course commences by introducing the History of Lean, the Toyota Production System, the 3M’s: Mura, Muri and Muda, and Taiichi Ohno’s famous Seven Wastes: Transportation, Inventory, Motion, Waiting, Over-Processing, Overproduction, Defects. Much of the course is about understanding and eliminating the Seven Wastes.

While learning about the 5 Whys, which is interesting enough as it is, who doesn’t want to know why the Titanic sank? Discovering that 5S is a concept about a systematic and sustainable method to organize and improve workplace environments. Furthermore, you learn that it removes waste from the workplace, improves quality and is a key element in an organization’s culture.

I also discovered the value in applying the 5S principles at home (in rooms and cupboards): get rid of clutter, find everything in place, keep everything clean and tidy, develop a system, and keep it going. It works and everyone is happier!

How is the course structured?

The course structure consists of recorded lectures, lecture transcripts, excellent lecture notes summarizing key concepts (PDFs), real life examples and case studies, practice questions to reinforce key learnings, and graded questions to track progress. And it all really works, the way the course is structured and flows, it just all makes sense, making it fun and easy to learn. And that’s not something you can always say!

You have the ability to save all the course content for future reference, allowing you to access the learning material when and where you like. You also have the flexibility to print the material or learn in a paperless environment. I preferred to print the lecture notes so I could further highlight what I considered key aspects from the lectures, that’s how I learn best but the choice is yours.

The course also presents guest lecturers from the industry who are experts in their field.

What is next?

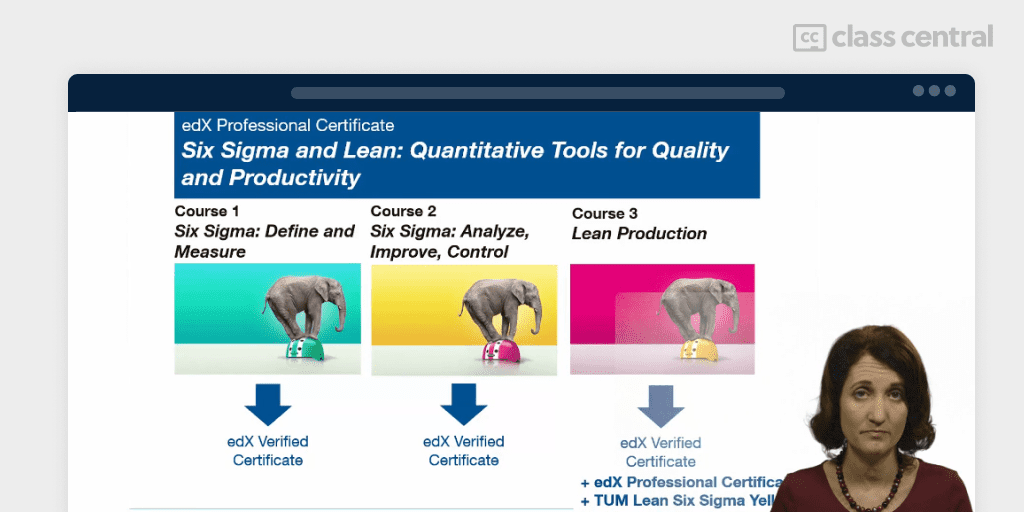

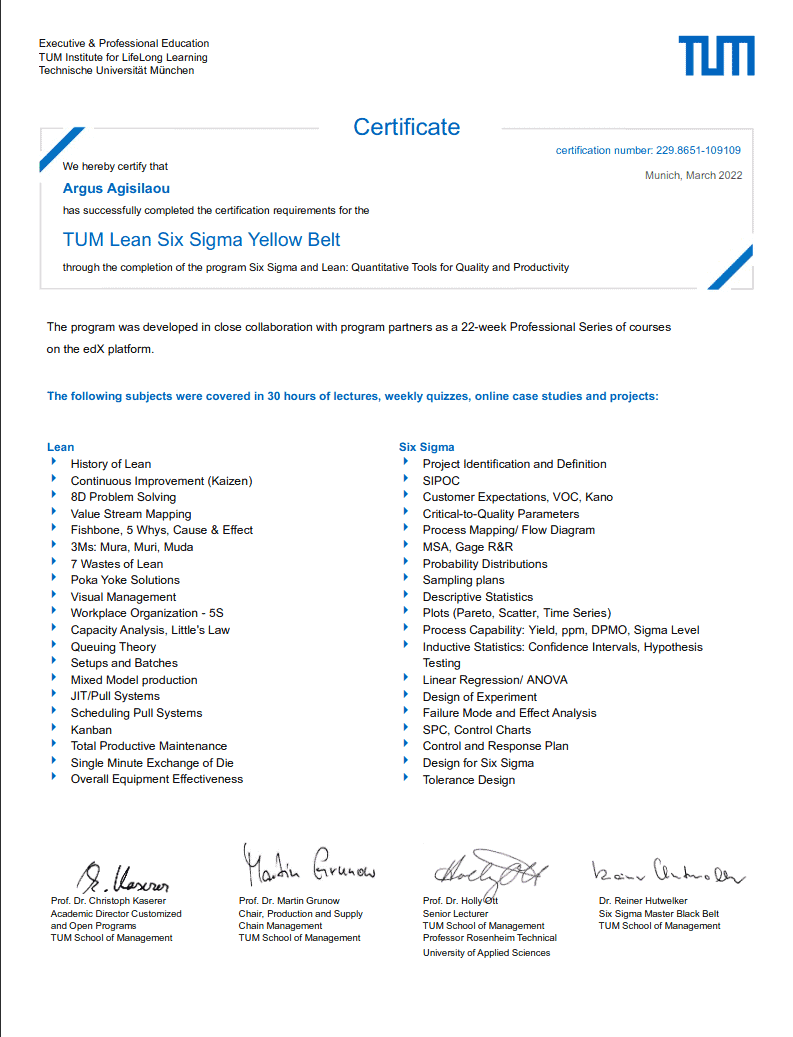

Lean Production is the third course of the edX Professional Certificate Lean Six Sigma Yellow Belt: Quantitative Tools for Quality and Productivity. Course 1 is Six Sigma: Define and Measure and Course 2 is Six Sigma: Analyze, Improve, and Control.

The courses can be taken separately, and the material of the courses is based on the American Society for Quality (ASQ) Body of Knowledge up to a Green Belt Level. Taken together, the three courses earn you a TUM Lean Six Sigma Yellow Belt certificate, which is the prerequisite for the Lean Six Sigma: Green Belt Certification Project.

With the TUM Yellow Belt, you have mastered the body of knowledge of the Green Belt according to the ASQ standards. To go from a Yellow to Green Belt, you implement a Lean Six Sigma improvement project (as recommended by the International Society of Six Sigma Professionals), just as the driving experience is necessary to obtain a driver’s license.

Having completed my Yellow Belt, this is the path I will take. As part of the route, I will drive along the DMAIC phases, applying the theory into a real-life end to end project that focuses on Environmental Littering, which is appealing on its own! Now with the necessary knowledge and foundation, which excites me, and is something I’m really looking forward to completing!